After printing a ton of stuff in PLA, I thought I’d try printing with a different material in my new Flashforge Creator Pro 2. I thought about ABS, but after doing some research online, temperature appeared to be a big concern, and there are some air gaps in the case Creator Pro 2, specifically the door handle and the top cover, so that led me to finding some models on Thingiverse, to help reduce the gaps, and it was recommended to use a flexible material. So I opted for TPU, specifically this Premium Flexible Filament (TPU) from Technology Outlet.

Flashforge Creator Pro 2 – Cover insert

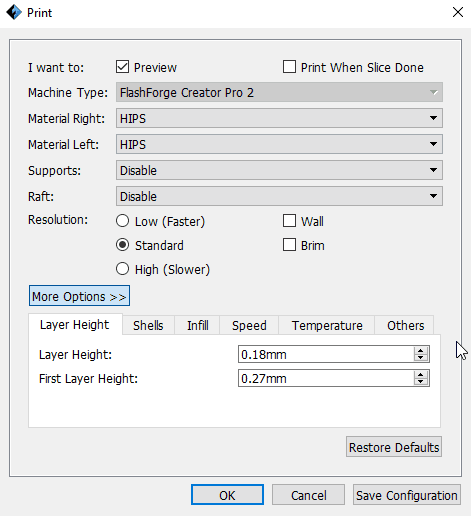

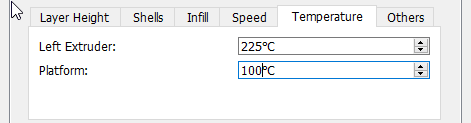

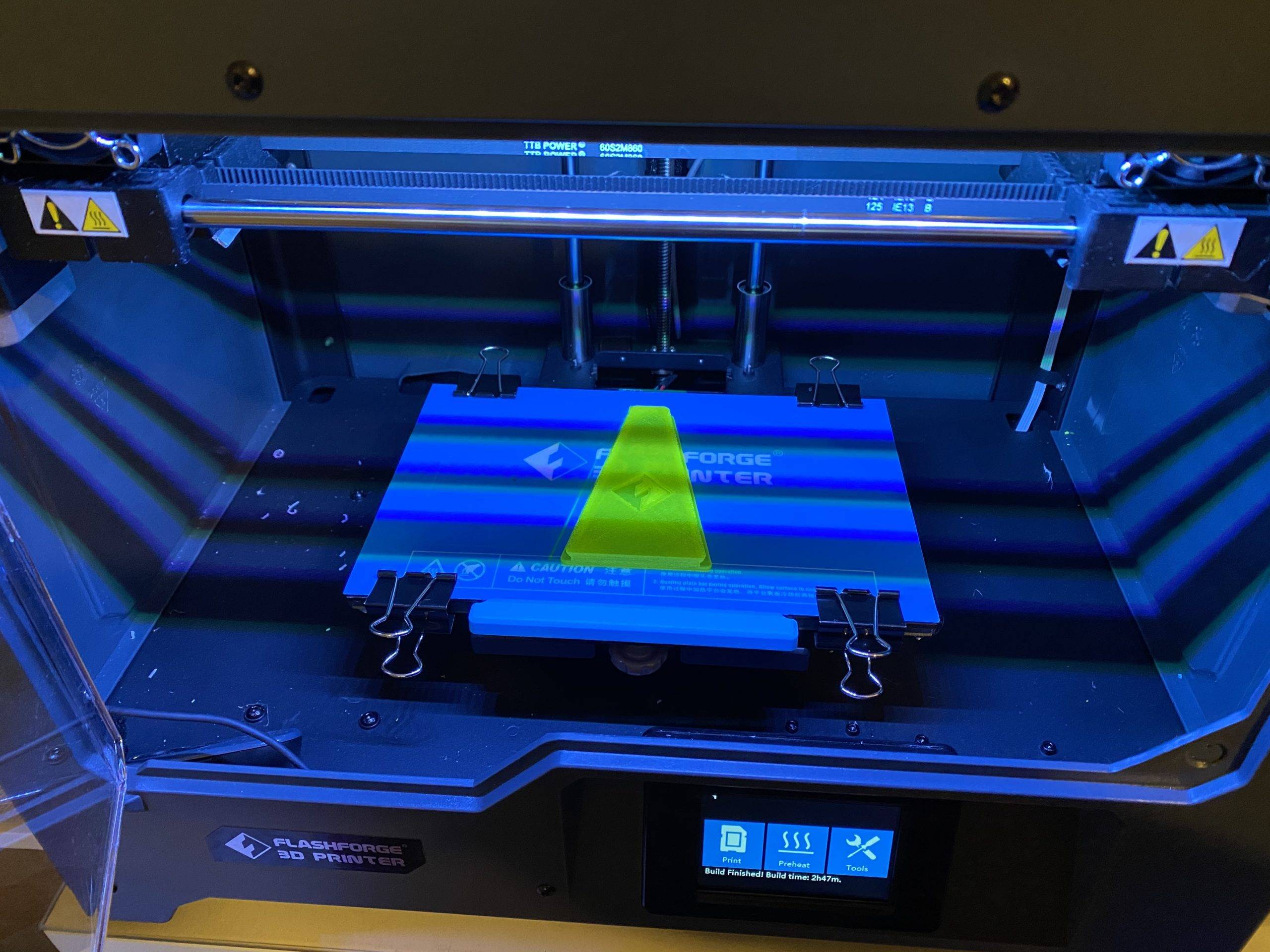

A neat little cover insert, was my first print with the TPU on the Creator Pro 2, and straight away, I had an issue. The TPU required a much higher temperature. So I bumped the extruder temperature up to 225°C, and the bed to 100°C, and it printed great, although I wish I’d gone for a higher resolution, but it’s fine and it does the job.

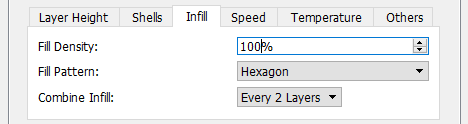

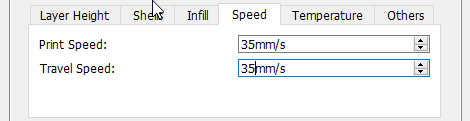

The Flash print settings I used were:

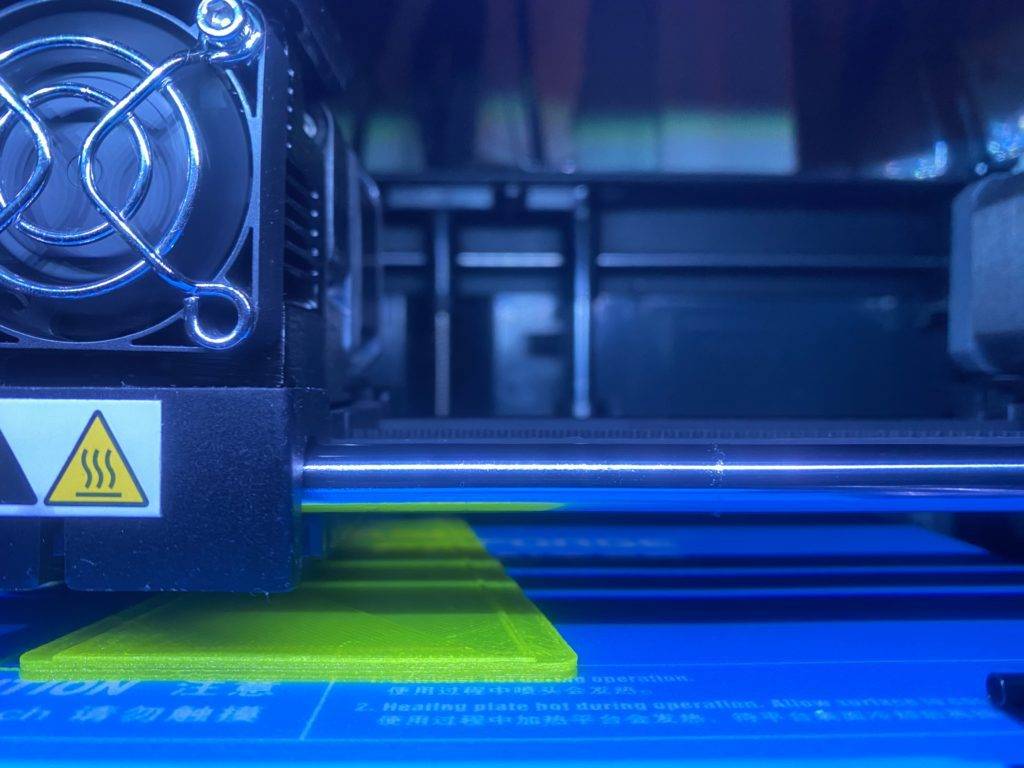

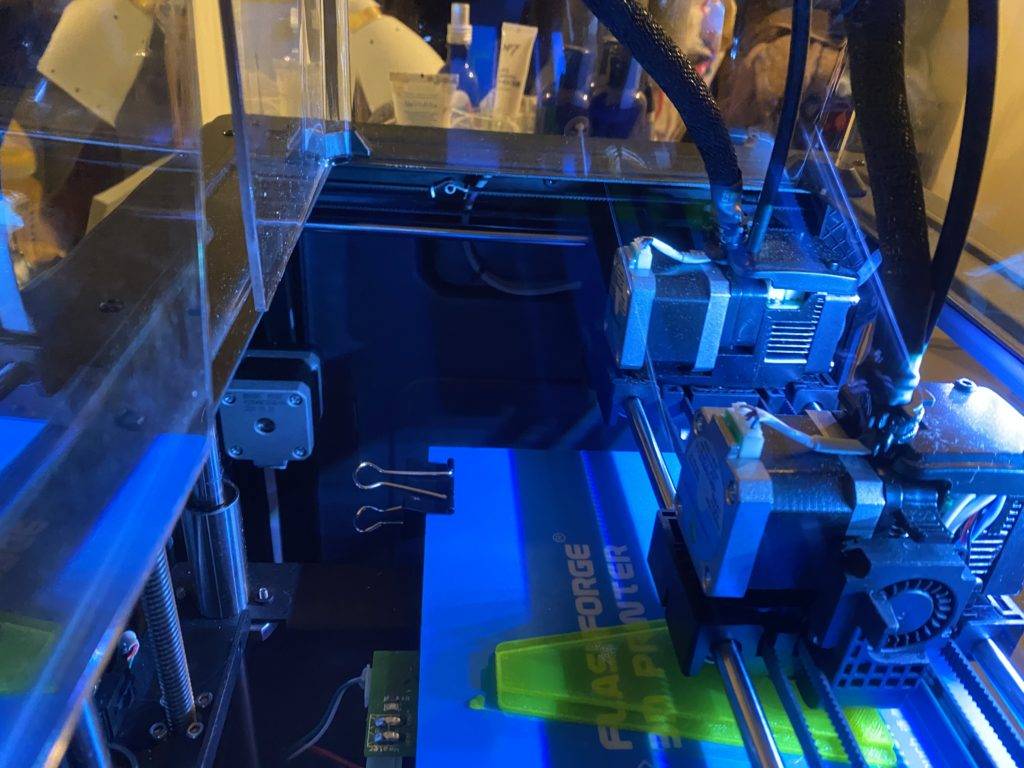

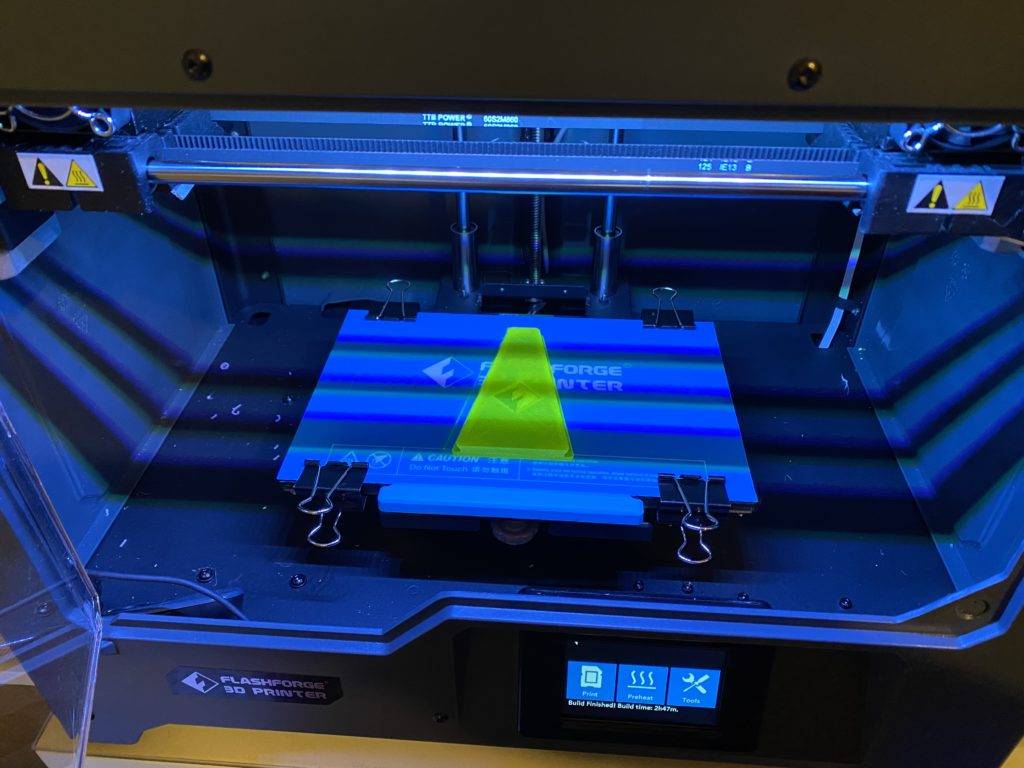

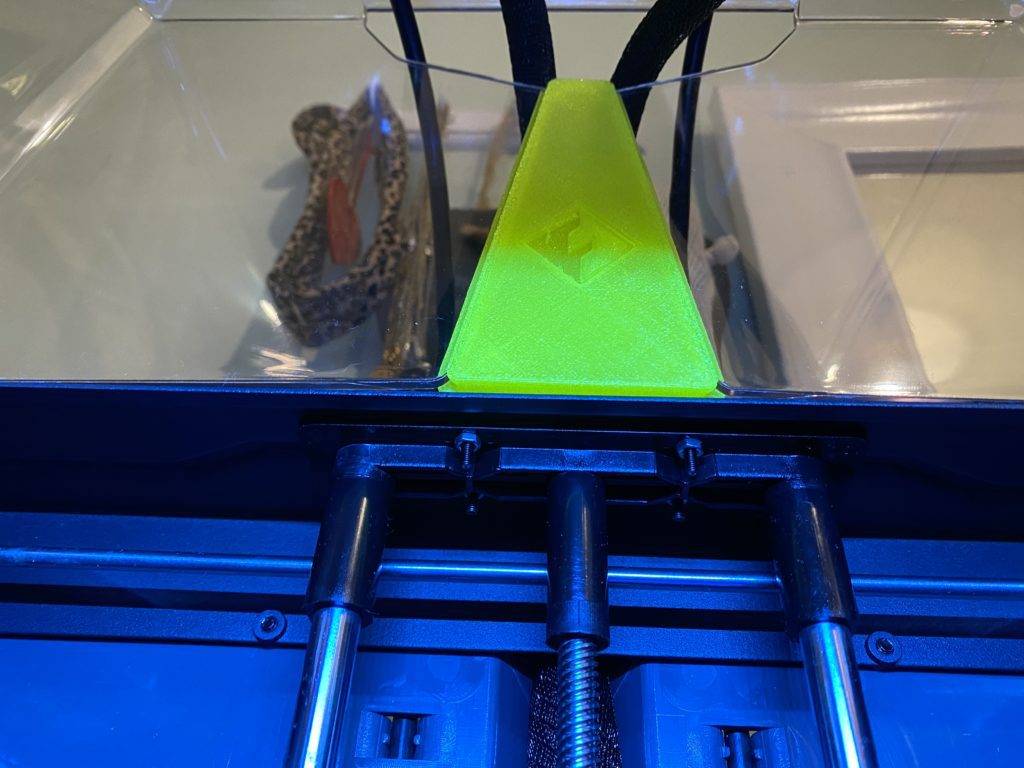

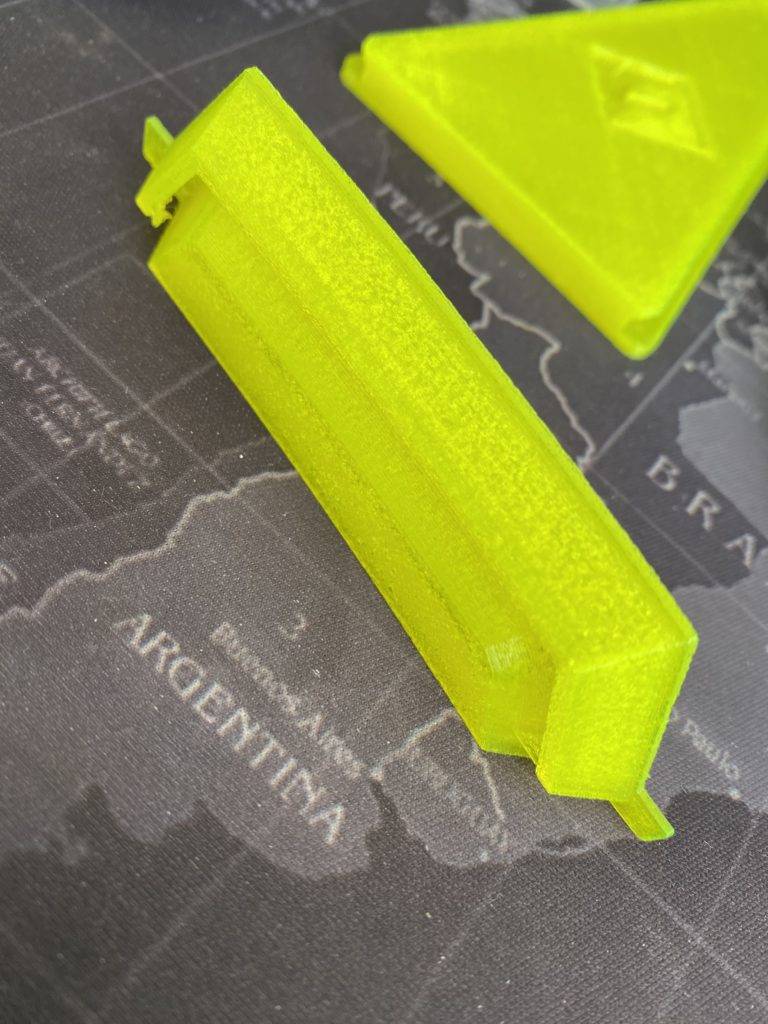

Here’s the print in various stages:

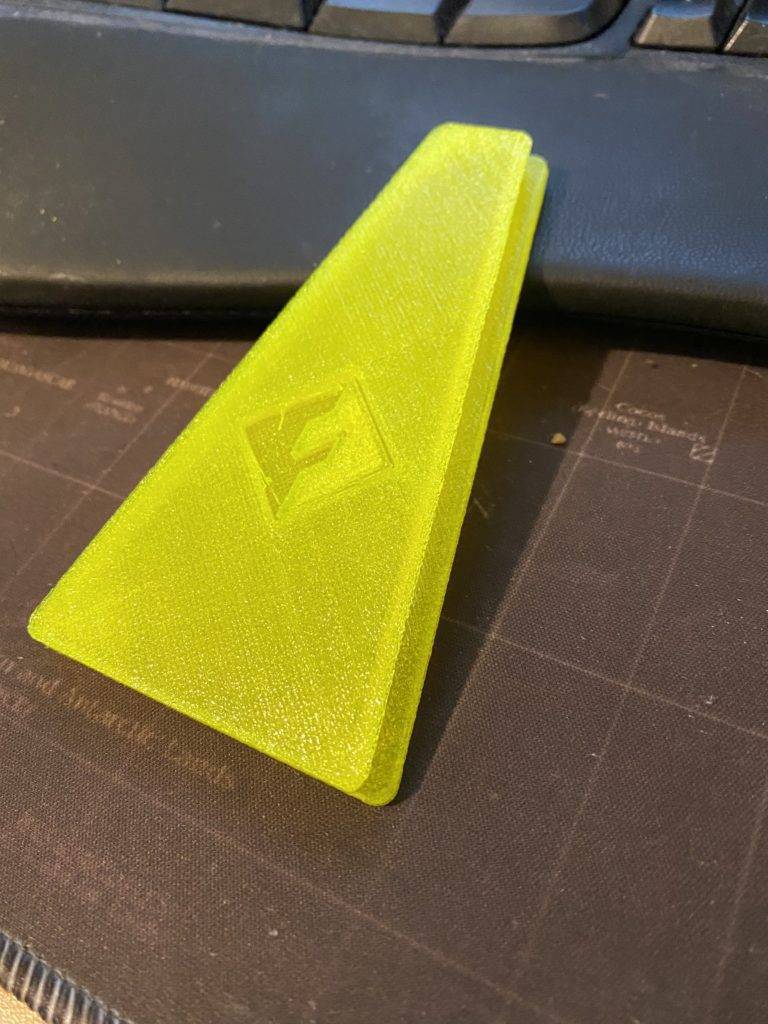

As you can see from the above shot, the TPU is quite flexible, even with a 100% fill. The model instructions do recommend a 20% fill, but I decided to go with 100%. You can download the model from: FlashForge Creator Pro hood insert 2.0. The model is actually for the 2016 version of the original V1 machine, but it fits the V2 model also.

Here’s what it looks like in place (photo taken from inside the Creator Pro 2):

Flashforge Creator Pro 2 – Door handle cover

At first, I didn’t really appreciate, or even notice, that the door handle on the Flashforge Creator Pro 2 is an air gap, but as you can see from the below photo, it’s quite big, well, it is if you want to avoid breezes and trying to maintain a temperature. Kids running in and out definitely don’t help 😉

So, this lead me to also print the a door handle, using this model: Flashforge Creator Pro Door Handle Draft/Warp Stopper. This model is also for the 2016 version of the original V1 machine, but it fits the V2 model also.

Anyway, so I kept the same settings, and within 5 minutes of the last print finishing, I started this one. It started well, I could see filament coming out, so I left it, but 30 minutes later, I only had one layer.

I removed the filament, to find a kink in it. I presume this is down to the fact that it had cooled, even though only for 5 or so minutes. I cut the kink out, fed the filament back in, and started the print again, and thankfully, it seemed to print ok. I’ll be checking this before each TPU print moving forward.

Here’s the final result.

My verdict on using TPU in the Flashforge Creator Pro 2

It works, but it does need some care, and a warm temperature. So it really comes down to your needs/wants. I probably won’t do a huge amount with it, but there are some practicle things I plan to do with it though, one day in the future.

Next, I’ll be printing some fun stuff 🙂

Let me know, in the comments below, if there’s anything you’d like me to try printing on the Flashforge Creator Pro 2, or perhaps a different material. I can’t promise I’ll do it, but I’m open to looking at it and doing it if I can.

Hi, more of a question rather than a comment. I’ve not yet tried to print TPU on my Flashforge Creator Pro 2; I’ve had great success on my other printers namely the Fokoos Odin and the CR6-SE, with these printers the bed is not heated, the extruders are usually between 220 and 225 and I usually get good prints. So why do you recommend having the Creator Pro 2 bed at 100 degrees, surely this is against all common consensus. If this is the way it needs to be to print with this printer then who am I to question it, especially if you are getting good prints. I will give it a try this evening and see if it produces decent prints for me. Thanks for your input.

To be honest, it was a while ago and I can’t remember, but it worked well for me at the time and the results were pretty good.

Sorry that doesn’t answer your question, I haven’t printed anything in a while. The machine is just too noisy and I haven’t had the time to replace the parts with quieter ones.